We aim at providing ingenuine, performance oriented and reliable well construction solutions.

Varel Energy Solutions is one of the world’s largest independent manufacturer and suppliers of downhole drilling and completions products to the energy sector. Headquartered in Houston, TX, VES services oil & gas, renewable energy, and industrial markets with its comprehensive suite of roller cone and fixed cutter drill bits as well as a complete portfolio of primary cementing equipment. The company employs more than 1,000 people and has manufacturing facilities in Matamoros, Mexico, Aberdeen, Scotland, Ibos, France, Dammam, Saudi Arabia, Kurgan, Russia, Houston, TX (starting 2021) as well as sales offices throughout the world. VES’s proprietary design capabilities, efficient manufacturing, and global sales force uniquely position the company to provide high-quality downhole solutions delivering reliable performance and a superior customer experience.

4730 Consulate Plaza Dr,, Houston, United States of America

Eastern Hemisphere Headquarters, Zone Europa 2 Rue Johannes Kepler Pau, 64000,

Ph: +x xxxxxxxxxx

Share this Page

( Click here to view email and contact)

Eastern Hemisphere Headquarters

Zone Europa 2 Rue Johannes Kepler

Contact Person :

Pau,

64000, France

Ph: +x xxxxxxxxxx

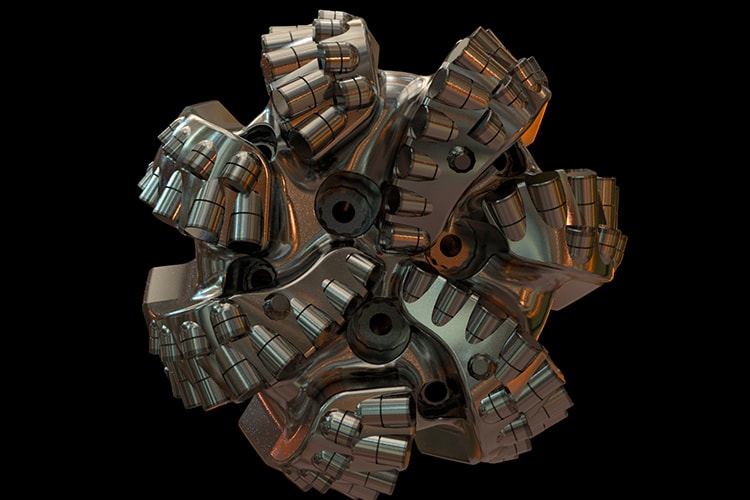

<p>VION PDC Tangent series has been developed specifically for applications where drilling through transitions requiring durability and control is essential.</p> <p>Designed from the start to handle the increased operating parameters of the new oilfield. Created with a balanced cutting structure profile adding greater bit stability to overcome the ROP and durability challenges of drilling transition zones and abrasive formations.</p> <p>Designed as a Solution Drill Bit:</p> <ul> <li>Tangent, Intermediate drilling intervals</li> <li>For soft to hard formations with transition zones</li> <li>For all rotary and PDM applications.</li> </ul> <p>Features :</p> <p>Utilizes, HYDRA, our hydraulically optimized attribute with curved nozzles, webbed blades, and designed junk slots improving performance in sticky formation applications.</p> <p>Balanced cutting structure leads to a toughened cone and strengthened nose and shoulder. A balanced bit design is more durable, faster drilling, and longer lived.</p> <p>Steel body option leads to a design that is faster and more aggressive than a matrix body bit but retains the toughness of a VION.</p> <p>VENOM Cutter methodology delivers the right cutter for any challenge.</p> <p>Source :- https://www.varel.com/drilling-solutions/vion</p>

<p>Designed as a Solution Drill Bit:</p> <ul> <li>Vertical, Directional, Horizontal, and Tangent wells</li> <li>For soft to hard formation drilling</li> <li>For all rotary, directional motor, and point-the-bit RSS applications</li> </ul> <p><strong>Source:- </strong>https://www.varel.com/drilling-solutions/bi-center</p>

<p style="box-sizing: border-box; border-width: 0px; border-style: solid; border-color: #e2e8f0; margin: 0px; font-family: interstate, sans-serif; font-size: medium; color: #221551;">SLIPSTREAM bits are specifically designed to target non-homogeneous downhole components such as bridge and frac plugs and are capable of handling the cast iron or ceramic slips as well as the softer core of those plugs. Tungsten carbide inserts and hardfaced steel teeth are arrayed in the cutting structure to cut both hard and soft materials found in frac plugs. High performance journal bearing and shirttail protection allow for both motor and rotary applications when drilling plugs or other downhole equipment.</p> <p> </p>

<p style="box-sizing: border-box; border-width: 0px; border-style: solid; border-color: #e2e8f0; margin: 0px; font-family: interstate, sans-serif; font-size: medium; color: #221551;">Unique Hybrid Cutting Technology Designed for Milling SlipXtreme is the latest generation of industry-leading hybrid cutting technology designed for milling. The new standard to the downhole product milling market and a revolutionary answer to isolation drill out and operational efficiency. The SlipXtreme is engineered to target non-homogeneous downhole components such with variability such as bridge and frac plugs as well as the more demanding requirements of cast iron or ceramic slips. Tungsten carbide inserts and hard-faced steel teeth are arrayed in the cutting structure to cut both hard and soft materials found in frac plugs. High performance journal bearing and shirttail protection allow for both motor and rotary applications when drilling plugs or other downhole equipment. As the newest generation design, the SlipXtreme delivers the highest standards in reliability and improved milling performance while extending the limits of what’s possible for customer well economics.</p>

<p style="box-sizing: border-box; border-width: 0px; border-style: solid; border-color: #e2e8f0; margin: 0px; font-family: interstate, sans-serif; font-size: medium; color: #221551;">Varel’s classic open bearing steel teeth bits for remedial, re-entry, and water well applications. All bits incorporate open throat hydraulics and can accommodate either regular through string flow or reverse circulation which is frequently used to re-enter wells. L2, L1, and LH1 are offered from softest to hardest of the cutting structure applications.</p> <p> </p>

<p><span style="color: #221551; font-family: interstate, sans-serif; font-size: 18px;">An industry leader in control line and ESP cable protection designed to reduce cable risks and prevent expensive workovers. The protection of downhole electrical cables is an essential measure to mitigate frequent failure events that often occur from various downhole operations, harsh environments and wellbore deviations. GRIPPY is reliable solution for both deployment safety and long-term sustainability of these lines/cables.</span></p>

<p>VION PDC Tangent series has been developed specifically for applications where drilling through transitions requiring durability and control is essential.</p> <p>Designed from the start to handle the increased operating parameters of the new oilfield. Created with a balanced cutting structure profile adding greater bit stability to overcome the ROP and durability challenges of drilling transition zones and abrasive formations.</p> <p>Designed as a Solution Drill Bit:</p> <ul> <li>Tangent, Intermediate drilling intervals</li> <li>For soft to hard formations with transition zones</li> <li>For all rotary and PDM applications.</li> </ul> <p>Features :</p> <p>Utilizes, HYDRA, our hydraulically optimized attribute with curved nozzles, webbed blades, and designed junk slots improving performance in sticky formation applications.</p> <p>Balanced cutting structure leads to a toughened cone and strengthened nose and shoulder. A balanced bit design is more durable, faster drilling, and longer lived.</p> <p>Steel body option leads to a design that is faster and more aggressive than a matrix body bit but retains the toughness of a VION.</p> <p>VENOM Cutter methodology delivers the right cutter for any challenge.</p> <p>Source :- https://www.varel.com/drilling-solutions/vion</p>

<p>Designed as a Solution Drill Bit:</p> <ul> <li>Vertical, Directional, Horizontal, and Tangent wells</li> <li>For soft to hard formation drilling</li> <li>For all rotary, directional motor, and point-the-bit RSS applications</li> </ul> <p><strong>Source:- </strong>https://www.varel.com/drilling-solutions/bi-center</p>

<p style="box-sizing: border-box; border-width: 0px; border-style: solid; border-color: #e2e8f0; margin: 0px; font-family: interstate, sans-serif; font-size: medium; color: #221551;">SLIPSTREAM bits are specifically designed to target non-homogeneous downhole components such as bridge and frac plugs and are capable of handling the cast iron or ceramic slips as well as the softer core of those plugs. Tungsten carbide inserts and hardfaced steel teeth are arrayed in the cutting structure to cut both hard and soft materials found in frac plugs. High performance journal bearing and shirttail protection allow for both motor and rotary applications when drilling plugs or other downhole equipment.</p> <p> </p>

<p style="box-sizing: border-box; border-width: 0px; border-style: solid; border-color: #e2e8f0; margin: 0px; font-family: interstate, sans-serif; font-size: medium; color: #221551;">Unique Hybrid Cutting Technology Designed for Milling SlipXtreme is the latest generation of industry-leading hybrid cutting technology designed for milling. The new standard to the downhole product milling market and a revolutionary answer to isolation drill out and operational efficiency. The SlipXtreme is engineered to target non-homogeneous downhole components such with variability such as bridge and frac plugs as well as the more demanding requirements of cast iron or ceramic slips. Tungsten carbide inserts and hard-faced steel teeth are arrayed in the cutting structure to cut both hard and soft materials found in frac plugs. High performance journal bearing and shirttail protection allow for both motor and rotary applications when drilling plugs or other downhole equipment. As the newest generation design, the SlipXtreme delivers the highest standards in reliability and improved milling performance while extending the limits of what’s possible for customer well economics.</p>

VION PDC Tangent series has been developed specifically for applications where drilling through transitions requiring durability and control is essential.

Designed from the start to handle the increased operating parameters of the new oilfield. Created with a balanced cutting structure profile adding greater bit stability to overcome the ROP and durability challenges of drilling transition zones and abrasive formations.

Designed as a Solution Drill Bit:

Features :

Utilizes, HYDRA, our hydraulically optimized attribute with curved nozzles, webbed blades, and designed junk slots improving performance in sticky formation applications.

Balanced cutting structure leads to a toughened cone and strengthened nose and shoulder. A balanced bit design is more durable, faster drilling, and longer lived.

Steel body option leads to a design that is faster and more aggressive than a matrix body bit but retains the toughness of a VION.

VENOM Cutter methodology delivers the right cutter for any challenge.

Source :- https://www.varel.com/drilling-solutions/vion

Designed as a Solution Drill Bit:

Source:- https://www.varel.com/drilling-solutions/bi-center

SLIPSTREAM bits are specifically designed to target non-homogeneous downhole components such as bridge and frac plugs and are capable of handling the cast iron or ceramic slips as well as the softer core of those plugs. Tungsten carbide inserts and hardfaced steel teeth are arrayed in the cutting structure to cut both hard and soft materials found in frac plugs. High performance journal bearing and shirttail protection allow for both motor and rotary applications when drilling plugs or other downhole equipment.

Unique Hybrid Cutting Technology Designed for Milling SlipXtreme is the latest generation of industry-leading hybrid cutting technology designed for milling. The new standard to the downhole product milling market and a revolutionary answer to isolation drill out and operational efficiency. The SlipXtreme is engineered to target non-homogeneous downhole components such with variability such as bridge and frac plugs as well as the more demanding requirements of cast iron or ceramic slips. Tungsten carbide inserts and hard-faced steel teeth are arrayed in the cutting structure to cut both hard and soft materials found in frac plugs. High performance journal bearing and shirttail protection allow for both motor and rotary applications when drilling plugs or other downhole equipment. As the newest generation design, the SlipXtreme delivers the highest standards in reliability and improved milling performance while extending the limits of what’s possible for customer well economics.

Varel’s classic open bearing steel teeth bits for remedial, re-entry, and water well applications. All bits incorporate open throat hydraulics and can accommodate either regular through string flow or reverse circulation which is frequently used to re-enter wells. L2, L1, and LH1 are offered from softest to hardest of the cutting structure applications.

An industry leader in control line and ESP cable protection designed to reduce cable risks and prevent expensive workovers. The protection of downhole electrical cables is an essential measure to mitigate frequent failure events that often occur from various downhole operations, harsh environments and wellbore deviations. GRIPPY is reliable solution for both deployment safety and long-term sustainability of these lines/cables.

Benchmark yourself against your main competitors

Peek into the hidden marketing strategies of your competitors, across industries and

Keyword research made easy and based on actual traffic statistics

Discover new opportunities while reducing risk by learning from your competitor's mistakess

Outbrain has been using SimilarWeb for over a year and it's been instrumental for our ability to analyze our competitive environment, benchmark our performance, keep track of industry trends, and generate new leads.