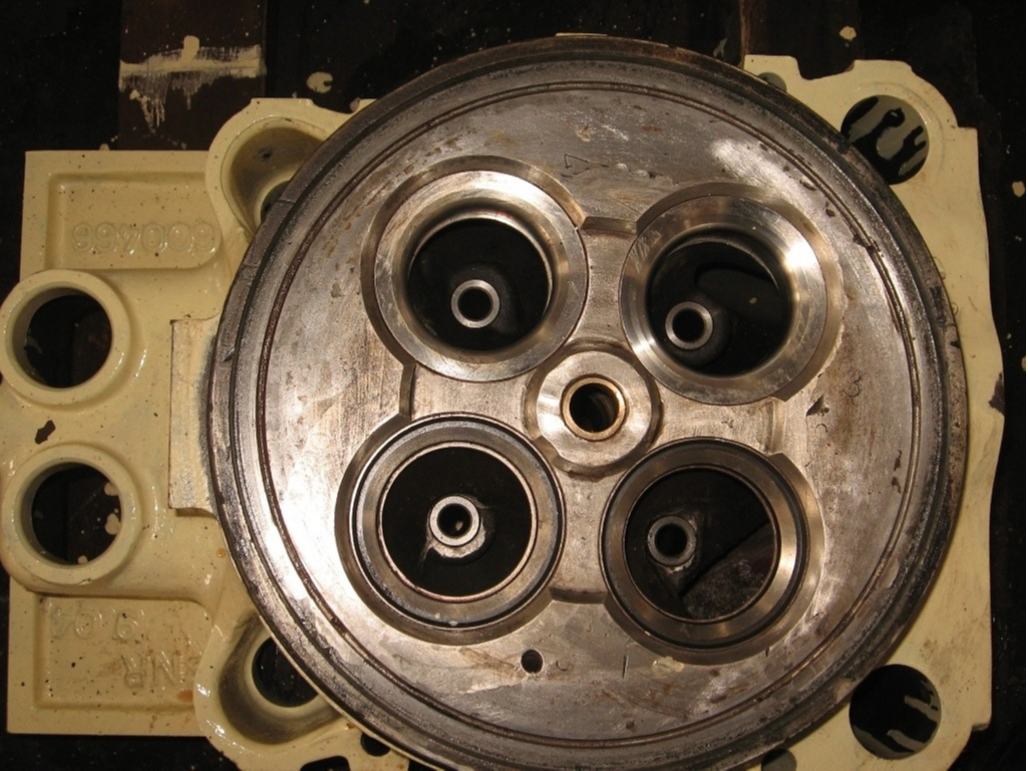

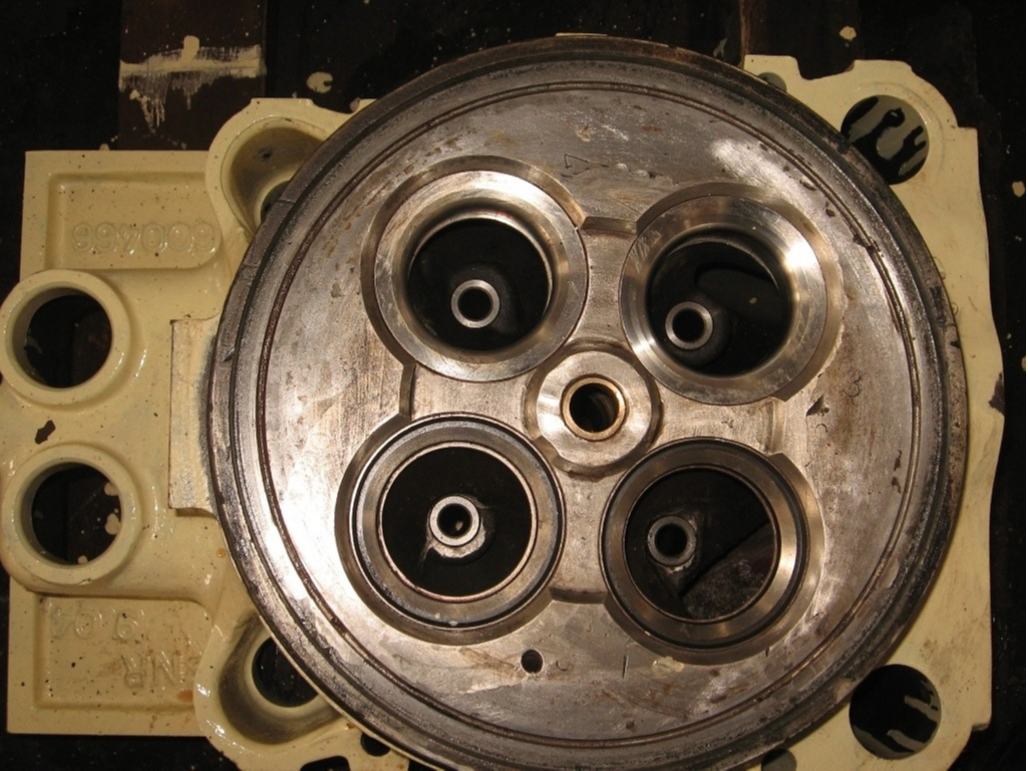

DIESEL ENGINE COMPONENTS

United Van Der Horst Ltd.

-

-

-

-

-

-

-

-

-

-

-

-

United Van Der Horst has successfully combined specialized welding technology and hard chrome plating technology for the complete reconditioning of damaged or worn out components of diesel engines such as a) Crankshafts b) Liners c) Cylinder Heads d) Exhaust Valves e) Connecting Rods f) Pistons g) Engine Blocks (Crank cases). Hard chrome plating of ring grooves of piston crown for better sealing and wear resistance, porous chrome of engine liners for improved lubrication, satellite inlay on seating face of valve seat and valve spindle for wear resistance, straightening of crankshaft and maintaining the bearing diameters to its original dimensions by hard chrome plating. Since the past 2 decades United Van Der Horst has served the Oil Field Industries with compete satisfaction. Our API certification has been a source of inspiration for continued improvement and up gradation. The entire procedure are approved by classification societies like IRS, DNV, BV, Lloyds.

Formed as a collaboration between the UB Group (India) and Dr. Van Der Horst B.V. (Holland) in 1989, United Van Der Horst (UVDHL) is a Public Limited Company. The firm provides reconditioning, re-standardizing, reverse engineering, and manufacturing services to the oil field and other core sectors such as marine, power plants, petrochemicals, mining and so on. United Van Der Horst has now become a part of one of the largest hydraulic, pneumatic and rotary seals and o-rings supplier, Max Spare.

The company prioritizes customer needs and consequently, has expanded its reach and capacity. In India, UVDHL is one of the largest service providers for all maintenance and breakdown needs. The company takes pride in successfully having provided services to the leading Indian companies like TATA, JSW, Reliance Industries, Mahindra, ONGC, SAIL, Essar, etc.

Products & Services

United Van Der Horst provides services for the equipment such as Blowout Preventers, Diesel Engine Components, Skidding gearbox, Mud pumps modules, Bull gear and shaft assemblies, Crankshaft, Pinion, Hub inboard/ hub outboard, Compressors, Rotor shaft, Column pipes, Actuators, and many others.

Blowout Preventer Services

United Van Der Horst provides replacement of damaged valve parts, testing at required pressure and dismantling of I-BOP. This BOP service provider offers all the services and reconditioning of all types of BOPs, i.e. Ram BOP, Annular BOP, and I-BOP’. The client’s needs and specifications are kept in mind while providing services.

Contact Information

For queries of BOP-related services and any other product services, contact United Van Der Horst on the given contact details:

Phone: +91-22-2741 2728 (10 lines)

Fax: +91-22-2741 2725 / 2741 0308

Product Code

-

Model Number

-

Condition Notes

-

Length

-

Height

-

Weight

-

Width

-

Shipping Length

-

Shipping Height

-

Shipping Weight

-

Shipping Width

-