DESCRIPTION

Stay on Target, Stay in Zone and Maximize Recovery

On time and in zone – the goals of directional drilling – sound easy enough? There are a lot of pieces that must be in place to ensure these goals are met and executed. From the right well plans to the proper motor configuration and experienced field personnel, there are many moving parts in any directional drilling operation.

At Cougar, we believe all of the pieces can fit together to maximize effectiveness and increase efficiency.

Collaboration

Starting from the operator’s request, we will collaborate with your team to fully understand the requirements of your upcoming drilling campaign, create a plan of action, come back to our teams with that information and design a fit-for-purpose directional plan to meet the needs discussed.

Well Planning

Next we will design a well plan based on your requirements and begin to design well specific BHAs for maximum effectiveness and time savings. This could include:

1. Drilling Motors

Having the right motor configuration, bend and stabilization can mean the difference to landing on plan or tripping out of hole for a secondary assembly. We utilize built-in-house motors and top-tier power sections to ensure we stay in hole and meet plan, every time.

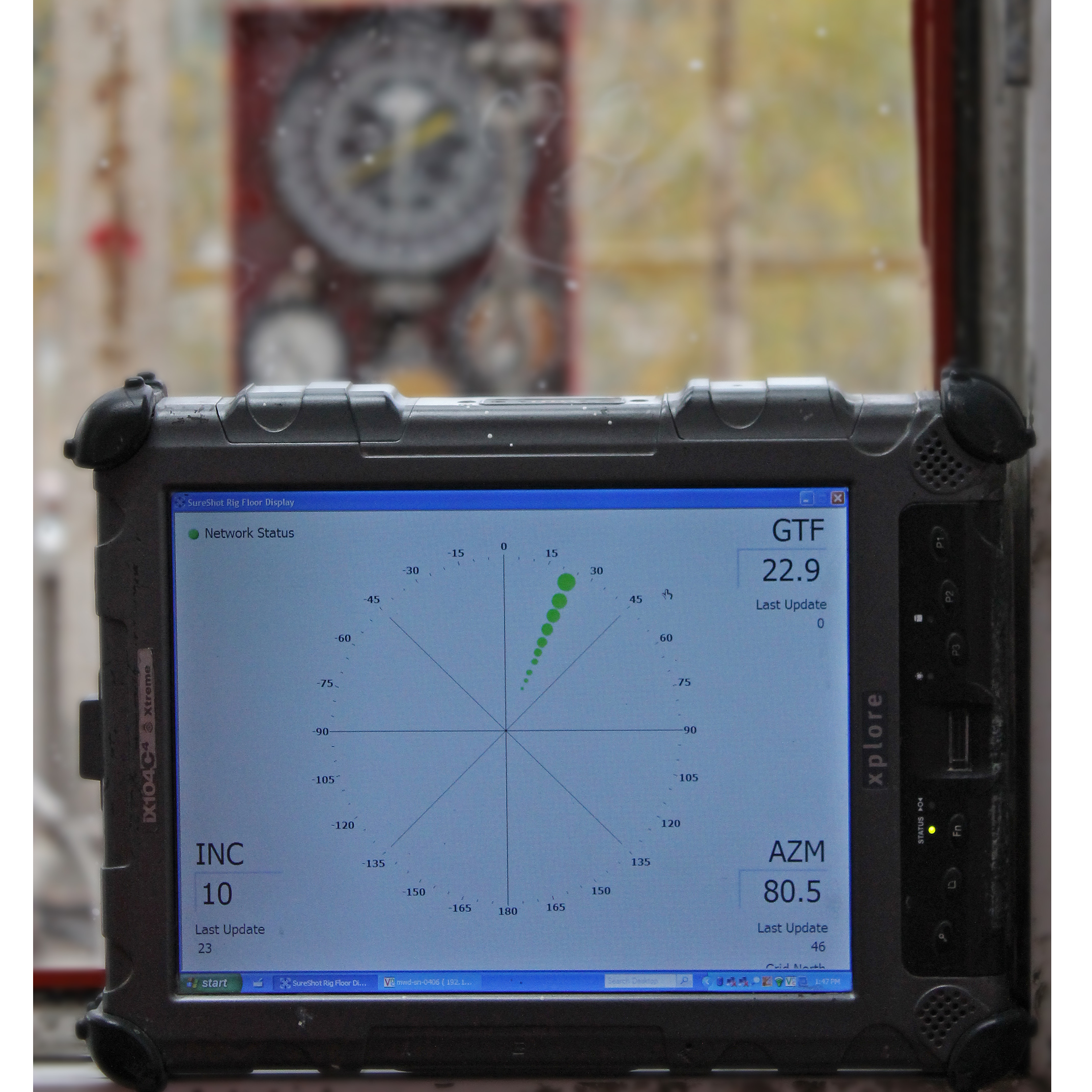

2. MWD

Without a robust, accurate MWD system, there is no way of knowing where in the ground your bit is drilling. Cutting corners is not an option. We hold our MWD facilities to the highest standards to ensure the surveys are pumped up on time, every time.

3. Stabilization

When designing an assembly for build, build and hold, hold or vertical control, stabilization is the key to performance. We will study these requirements and utilize our in-house machining capabilities to make sure the stabilizers are cut to the accurate OD, gauge and taper for maximum effectiveness, every time.

Other Tools and Services

RSS – Rotary steerable systems are available for use by Cougar in parts of the MENA region. These tools will allow the operator to continue rotating thru build sections instead of putting in timely slides. This will allow you to drill faster, reduce DLS and create a smooth wellbore for your casing, completions and production teams to have the best shot at success.

LWD – Logging while drilling is the use of gamma ray, resistivity, porosity, density and nuclear source to provide an accurate image of the available resource to be recovered. This provides insight and understanding to the operator as to where this well should be placed (geosteering) what potential recovery should be, and where the following offset well campaigns should be placed.

Ready to start? Ask how Cougar engineers can provide efficient, cost-effective directional drilling services customized for your well.