We take care of the wear protection needs of all your piping equipments.

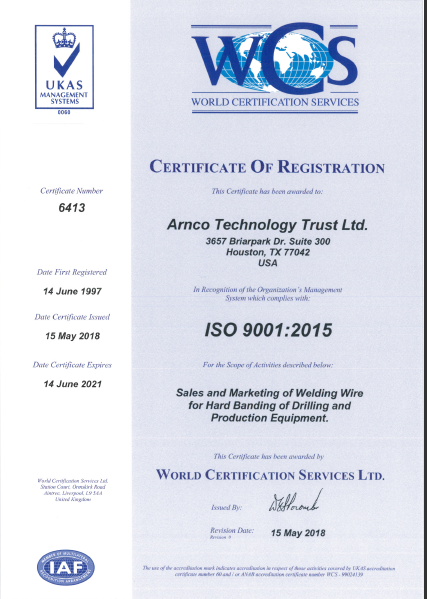

Arnco provides industry-leading, wear-resistant hardbanding alloys for the worldwide petroleum industry. As a global leader in wear-resistant, casing-friendly hardbanding alloys we provide top tier protection for your drill pipe, casing, and tubing. We also provide hardbanding reapplication services in the USA using our fleet of mobile hardbanding units and our highly-trained personnel. Arnco Technology has led the hardbanding industry since pioneering the use of casing-friendly hardbanding two decades ago. We pride ourselves on protecting your drill string and casing assets by developing leading edge solutions for ultimate wear protection and crack-free products.

3657 Briarpark Dr, Suite 300, Houston, United States of America

Year of incorporation

2002

Year of incorporation

2002

<p>300XT™ has long been considered the industry’s most wear-resistant hardbanding product and is a favored choice by many international operators and drilling contractors for drill pipe and casing protection. 300XT™ is known to consistently outlast the competition in lab and field tests. It produces minimum casing wear and maintains significantly more open-hole wear resistance versus competing casing-friendly products – qualities needed to protect the drill pipe tool joints from rapid wear found in highly abrasive drilling conditions.</p> <p>For customers seeking the durability of the 300XT™ with improved ease of application and the ability to re-apply over competitive materials, the 300XT™ should be considered.</p> <p>Benefits:-</p> <ul> <li>Extremely Durable and Long-Lasting</li> <li>Very Casing-Friendly</li> <li>Able to be Reapplied Over Itself</li> <li>Acceptable Micro-Cracks</li> </ul> <p>Source :- https://www.arncotech.com/300-xt/</p>

<p>Arnco 100XT™ was created using an innovative metallurgical design that delivers both adequate tool joint protection and excellent casing wear protection. Arnco 100XT™ delivers a crack-free deposit and exhibits casing wear among the lowest ever measured.</p> <p>The inherently low coefficient of friction that is a feature of Arnco 100XT™’s metallurgical characteristics significantly reduces wear caused by contact between the drill string, casing and marine risers and BOPs and can extend the economic life of all the equipment involved.</p> <p>Arnco is proud of the 100XT™ with it’s proven track record since the late 1990’s as one of our legacy products. The key features of the 100XT™ wire is the non-cracking hardbanding and casing friendliness to maximize casing protection. For customers looking for a casing friendly only specification, the 100XT™ is easily the best choice.</p> <p>Benefits:-</p> <ul> <li>Arnco’s Original Non-Cracking Alloy</li> <li>Casing-Friendly</li> <li>Non-Cracking</li> <li>No Spalling or Chipping</li> <li>Re-Application Without Previous Layer Removal</li> </ul> <p>Source :- https://www.arncotech.com/100-xt/</p>

<p>Arnco’s BUXT™ is a high-quality, metal-cored wire for all build-up needs. Ideal for welding onto most steels comprising tubulars in the oilfield, BUXT™ is an easy-to-apply welding wire that produces a smooth weld bead free of cracks. Arnco’s BUXT™ is the ideal build-up wire to complement any of Arnco’s line of hardbanding products.</p> <p>Benefits:-</p> <ul> <li>Premium Metal-Cored Build-Up Wire</li> <li>Produces a Smooth, High-Compatibility Weld Deposit</li> <li>Apply Multiple Layers for Build Up as Necessary</li> <li>Easily Machinable After Welding</li> </ul> <p>Source :- https://www.arncotech.com/buxt/</p>

<p>Arnco’s 350XT® is a metal-cored wire that produces a highly wear-resistant, hard (greater than 60 HRC), tough, and casing-friendly, NON-CRACKING deposit. The ability to achieve such exceptional durability, while being casing-friendly and crack-free, is metallurgically based on carbides and borides that produce a grain structure forming tightly arranged hard phases interspersed in a strong, ductile matrix. The small nature of the carbides and borides puts less stress on the matrix allowing for a crack-free deposit and superior durability.</p> <p>350XT® can easily be applied on new tooljoints or re-applied over itself without removal of the previous layer. The material can also be applied over Arnco’s 100XT™ and 150XT™, as well as most comparable products with proper procedures. When applied, 350XT® produces a smooth, crack-free deposit with very little spatter, requiring minimal post-weld cleanup. With 350XT®’s best-in-class wear resistance for non-cracking hardbanding solutions, you won’t need to reapply as often as competing products, improving your ROI. As the most durable, casing-friendly, and non-cracking hardbanding solution on the market you can’t go wrong with Arnco’s 350XT®.</p> <p>Benefits :-</p> <ul> <li>Compatible With Every Major Hardbanding Product</li> <li>Industry-Best Tool Joint Protection</li> <li>Very Casing-Friendly</li> <li>Non-Cracking (Single and Double Layer)</li> <li>No Spalling, Chipping, or Flaking</li> <li>Re-Application Without Previous Layer Removal</li> </ul> <p>Source :- https://www.arncotech.com/350-xt/</p>

<p>Arnco’s 150XT™ is a durable, casing-friendly, and crack-free hardbanding wire and maintains the industry’s lowest casing wear rate for tool joint protection. The 150XT™ product was developed to be a crack-free, competitively priced hardbanding product with extremely low casing wear and high wear resistance for tool-joint protection. 150XT™ is a perfect solution to reduce the casing wear in areas of high side loading.</p> <p>After years of continued success with Arnco’s legacy 100XT™, we set out to develop a hardbanding material with significantly improved durability while still maintaining the industry’s lowest casing wear rate. As a result, we developed 150XT™. With quadruple the wear resistance and double the durability as 100XT™, as well as being Arnco’s most casing-friendly product to date, we know we succeeded. For our customers seeking a balance between price, casing-friendliness and durability, 150XT™ offers the best hardbanding solution available.</p> <p> </p> <p>The 150XT™ product is easy to apply and exhibits excellent weldability. It produces a smooth, crack-free deposit with very little spatter requiring minimal post-weld clean-up. 150XT™ is a similar compound to the 300XT™, except this wire is a non-cracking hardbanding solution. 150XT™ can be applied over itself an unlimited number of times without removal of the previous layer. It may also be applied over Arnco’s 100XT™ and 350XT®, as well as most comparable products using proper procedures.</p> <p>Benefits :-</p> <ul> <li>Compatible With Every Major Hardbanding Product</li> <li>Extremely Casing-Friendly</li> <li>Exceptional Durability</li> <li>Non-Cracking</li> <li>No Spalling, Chipping, or Flaking</li> <li>Re-Application Without Previous Layer Removal</li> <li>Highly H2S resistant</li> </ul> <p>Source :- https://www.arncotech.com/150-xt/</p>

<p>300XT™ has long been considered the industry’s most wear-resistant hardbanding product and is a favored choice by many international operators and drilling contractors for drill pipe and casing protection. 300XT™ is known to consistently outlast the competition in lab and field tests. It produces minimum casing wear and maintains significantly more open-hole wear resistance versus competing casing-friendly products – qualities needed to protect the drill pipe tool joints from rapid wear found in highly abrasive drilling conditions.</p> <p>For customers seeking the durability of the 300XT™ with improved ease of application and the ability to re-apply over competitive materials, the 300XT™ should be considered.</p> <p>Benefits:-</p> <ul> <li>Extremely Durable and Long-Lasting</li> <li>Very Casing-Friendly</li> <li>Able to be Reapplied Over Itself</li> <li>Acceptable Micro-Cracks</li> </ul> <p>Source :- https://www.arncotech.com/300-xt/</p>

<p>Arnco 100XT™ was created using an innovative metallurgical design that delivers both adequate tool joint protection and excellent casing wear protection. Arnco 100XT™ delivers a crack-free deposit and exhibits casing wear among the lowest ever measured.</p> <p>The inherently low coefficient of friction that is a feature of Arnco 100XT™’s metallurgical characteristics significantly reduces wear caused by contact between the drill string, casing and marine risers and BOPs and can extend the economic life of all the equipment involved.</p> <p>Arnco is proud of the 100XT™ with it’s proven track record since the late 1990’s as one of our legacy products. The key features of the 100XT™ wire is the non-cracking hardbanding and casing friendliness to maximize casing protection. For customers looking for a casing friendly only specification, the 100XT™ is easily the best choice.</p> <p>Benefits:-</p> <ul> <li>Arnco’s Original Non-Cracking Alloy</li> <li>Casing-Friendly</li> <li>Non-Cracking</li> <li>No Spalling or Chipping</li> <li>Re-Application Without Previous Layer Removal</li> </ul> <p>Source :- https://www.arncotech.com/100-xt/</p>

<p>Arnco’s BUXT™ is a high-quality, metal-cored wire for all build-up needs. Ideal for welding onto most steels comprising tubulars in the oilfield, BUXT™ is an easy-to-apply welding wire that produces a smooth weld bead free of cracks. Arnco’s BUXT™ is the ideal build-up wire to complement any of Arnco’s line of hardbanding products.</p> <p>Benefits:-</p> <ul> <li>Premium Metal-Cored Build-Up Wire</li> <li>Produces a Smooth, High-Compatibility Weld Deposit</li> <li>Apply Multiple Layers for Build Up as Necessary</li> <li>Easily Machinable After Welding</li> </ul> <p>Source :- https://www.arncotech.com/buxt/</p>

<p>Arnco’s 350XT® is a metal-cored wire that produces a highly wear-resistant, hard (greater than 60 HRC), tough, and casing-friendly, NON-CRACKING deposit. The ability to achieve such exceptional durability, while being casing-friendly and crack-free, is metallurgically based on carbides and borides that produce a grain structure forming tightly arranged hard phases interspersed in a strong, ductile matrix. The small nature of the carbides and borides puts less stress on the matrix allowing for a crack-free deposit and superior durability.</p> <p>350XT® can easily be applied on new tooljoints or re-applied over itself without removal of the previous layer. The material can also be applied over Arnco’s 100XT™ and 150XT™, as well as most comparable products with proper procedures. When applied, 350XT® produces a smooth, crack-free deposit with very little spatter, requiring minimal post-weld cleanup. With 350XT®’s best-in-class wear resistance for non-cracking hardbanding solutions, you won’t need to reapply as often as competing products, improving your ROI. As the most durable, casing-friendly, and non-cracking hardbanding solution on the market you can’t go wrong with Arnco’s 350XT®.</p> <p>Benefits :-</p> <ul> <li>Compatible With Every Major Hardbanding Product</li> <li>Industry-Best Tool Joint Protection</li> <li>Very Casing-Friendly</li> <li>Non-Cracking (Single and Double Layer)</li> <li>No Spalling, Chipping, or Flaking</li> <li>Re-Application Without Previous Layer Removal</li> </ul> <p>Source :- https://www.arncotech.com/350-xt/</p>

<p>Arnco’s 150XT™ is a durable, casing-friendly, and crack-free hardbanding wire and maintains the industry’s lowest casing wear rate for tool joint protection. The 150XT™ product was developed to be a crack-free, competitively priced hardbanding product with extremely low casing wear and high wear resistance for tool-joint protection. 150XT™ is a perfect solution to reduce the casing wear in areas of high side loading.</p> <p>After years of continued success with Arnco’s legacy 100XT™, we set out to develop a hardbanding material with significantly improved durability while still maintaining the industry’s lowest casing wear rate. As a result, we developed 150XT™. With quadruple the wear resistance and double the durability as 100XT™, as well as being Arnco’s most casing-friendly product to date, we know we succeeded. For our customers seeking a balance between price, casing-friendliness and durability, 150XT™ offers the best hardbanding solution available.</p> <p> </p> <p>The 150XT™ product is easy to apply and exhibits excellent weldability. It produces a smooth, crack-free deposit with very little spatter requiring minimal post-weld clean-up. 150XT™ is a similar compound to the 300XT™, except this wire is a non-cracking hardbanding solution. 150XT™ can be applied over itself an unlimited number of times without removal of the previous layer. It may also be applied over Arnco’s 100XT™ and 350XT®, as well as most comparable products using proper procedures.</p> <p>Benefits :-</p> <ul> <li>Compatible With Every Major Hardbanding Product</li> <li>Extremely Casing-Friendly</li> <li>Exceptional Durability</li> <li>Non-Cracking</li> <li>No Spalling, Chipping, or Flaking</li> <li>Re-Application Without Previous Layer Removal</li> <li>Highly H2S resistant</li> </ul> <p>Source :- https://www.arncotech.com/150-xt/</p>

<p>300XT™ has long been considered the industry’s most wear-resistant hardbanding product and is a favored choice by many international operators and drilling contractors for drill pipe and casing protection. 300XT™ is known to consistently outlast the competition in lab and field tests. It produces minimum casing wear and maintains significantly more open-hole wear resistance versus competing casing-friendly products – qualities needed to protect the drill pipe tool joints from rapid wear found in highly abrasive drilling conditions.</p> <p>For customers seeking the durability of the 300XT™ with improved ease of application and the ability to re-apply over competitive materials, the 300XT™ should be considered.</p> <p>Benefits:-</p> <ul> <li>Extremely Durable and Long-Lasting</li> <li>Very Casing-Friendly</li> <li>Able to be Reapplied Over Itself</li> <li>Acceptable Micro-Cracks</li> </ul> <p>Source :- https://www.arncotech.com/300-xt/</p>

<p>Arnco 100XT™ was created using an innovative metallurgical design that delivers both adequate tool joint protection and excellent casing wear protection. Arnco 100XT™ delivers a crack-free deposit and exhibits casing wear among the lowest ever measured.</p> <p>The inherently low coefficient of friction that is a feature of Arnco 100XT™’s metallurgical characteristics significantly reduces wear caused by contact between the drill string, casing and marine risers and BOPs and can extend the economic life of all the equipment involved.</p> <p>Arnco is proud of the 100XT™ with it’s proven track record since the late 1990’s as one of our legacy products. The key features of the 100XT™ wire is the non-cracking hardbanding and casing friendliness to maximize casing protection. For customers looking for a casing friendly only specification, the 100XT™ is easily the best choice.</p> <p>Benefits:-</p> <ul> <li>Arnco’s Original Non-Cracking Alloy</li> <li>Casing-Friendly</li> <li>Non-Cracking</li> <li>No Spalling or Chipping</li> <li>Re-Application Without Previous Layer Removal</li> </ul> <p>Source :- https://www.arncotech.com/100-xt/</p>

Arnco’s 150XT™ is a durable, casing-friendly, and crack-free hardbanding wire and maintains the industry’s lowest casing wear rate for tool joint protection. The 150XT™ product was developed to be a crack-free, competitively priced hardbanding product with extremely low casing wear and high wear resistance for tool-joint protection. 150XT™ is a perfect solution to reduce the casing wear in areas of high side loading.

After years of continued success with Arnco’s legacy 100XT™, we set out to develop a hardbanding material with significantly improved durability while still maintaining the industry’s lowest casing wear rate. As a result, we developed 150XT™. With quadruple the wear resistance and double the durability as 100XT™, as well as being Arnco’s most casing-friendly product to date, we know we succeeded. For our customers seeking a balance between price, casing-friendliness and durability, 150XT™ offers the best hardbanding solution available.

The 150XT™ product is easy to apply and exhibits excellent weldability. It produces a smooth, crack-free deposit with very little spatter requiring minimal post-weld clean-up. 150XT™ is a similar compound to the 300XT™, except this wire is a non-cracking hardbanding solution. 150XT™ can be applied over itself an unlimited number of times without removal of the previous layer. It may also be applied over Arnco’s 100XT™ and 350XT®, as well as most comparable products using proper procedures.

Benefits :-

Source :- https://www.arncotech.com/150-xt/

300XT™ has long been considered the industry’s most wear-resistant hardbanding product and is a favored choice by many international operators and drilling contractors for drill pipe and casing protection. 300XT™ is known to consistently outlast the competition in lab and field tests. It produces minimum casing wear and maintains significantly more open-hole wear resistance versus competing casing-friendly products – qualities needed to protect the drill pipe tool joints from rapid wear found in highly abrasive drilling conditions.

For customers seeking the durability of the 300XT™ with improved ease of application and the ability to re-apply over competitive materials, the 300XT™ should be considered.

Benefits:-

Source :- https://www.arncotech.com/300-xt/

Arnco 100XT™ was created using an innovative metallurgical design that delivers both adequate tool joint protection and excellent casing wear protection. Arnco 100XT™ delivers a crack-free deposit and exhibits casing wear among the lowest ever measured.

The inherently low coefficient of friction that is a feature of Arnco 100XT™’s metallurgical characteristics significantly reduces wear caused by contact between the drill string, casing and marine risers and BOPs and can extend the economic life of all the equipment involved.

Arnco is proud of the 100XT™ with it’s proven track record since the late 1990’s as one of our legacy products. The key features of the 100XT™ wire is the non-cracking hardbanding and casing friendliness to maximize casing protection. For customers looking for a casing friendly only specification, the 100XT™ is easily the best choice.

Benefits:-

Source :- https://www.arncotech.com/100-xt/

Arnco’s BUXT™ is a high-quality, metal-cored wire for all build-up needs. Ideal for welding onto most steels comprising tubulars in the oilfield, BUXT™ is an easy-to-apply welding wire that produces a smooth weld bead free of cracks. Arnco’s BUXT™ is the ideal build-up wire to complement any of Arnco’s line of hardbanding products.

Benefits:-

Source :- https://www.arncotech.com/buxt/

Arnco’s 350XT® is a metal-cored wire that produces a highly wear-resistant, hard (greater than 60 HRC), tough, and casing-friendly, NON-CRACKING deposit. The ability to achieve such exceptional durability, while being casing-friendly and crack-free, is metallurgically based on carbides and borides that produce a grain structure forming tightly arranged hard phases interspersed in a strong, ductile matrix. The small nature of the carbides and borides puts less stress on the matrix allowing for a crack-free deposit and superior durability.

350XT® can easily be applied on new tooljoints or re-applied over itself without removal of the previous layer. The material can also be applied over Arnco’s 100XT™ and 150XT™, as well as most comparable products with proper procedures. When applied, 350XT® produces a smooth, crack-free deposit with very little spatter, requiring minimal post-weld cleanup. With 350XT®’s best-in-class wear resistance for non-cracking hardbanding solutions, you won’t need to reapply as often as competing products, improving your ROI. As the most durable, casing-friendly, and non-cracking hardbanding solution on the market you can’t go wrong with Arnco’s 350XT®.

Benefits :-

Source :- https://www.arncotech.com/350-xt/

Arnco’s 150XT™ is a durable, casing-friendly, and crack-free hardbanding wire and maintains the industry’s lowest casing wear rate for tool joint protection. The 150XT™ product was developed to be a crack-free, competitively priced hardbanding product with extremely low casing wear and high wear resistance for tool-joint protection. 150XT™ is a perfect solution to reduce the casing wear in areas of high side loading.

After years of continued success with Arnco’s legacy 100XT™, we set out to develop a hardbanding material with significantly improved durability while still maintaining the industry’s lowest casing wear rate. As a result, we developed 150XT™. With quadruple the wear resistance and double the durability as 100XT™, as well as being Arnco’s most casing-friendly product to date, we know we succeeded. For our customers seeking a balance between price, casing-friendliness and durability, 150XT™ offers the best hardbanding solution available.

The 150XT™ product is easy to apply and exhibits excellent weldability. It produces a smooth, crack-free deposit with very little spatter requiring minimal post-weld clean-up. 150XT™ is a similar compound to the 300XT™, except this wire is a non-cracking hardbanding solution. 150XT™ can be applied over itself an unlimited number of times without removal of the previous layer. It may also be applied over Arnco’s 100XT™ and 350XT®, as well as most comparable products using proper procedures.

Benefits :-

Source :- https://www.arncotech.com/150-xt/

300XT™ has long been considered the industry’s most wear-resistant hardbanding product and is a favored choice by many international operators and drilling contractors for drill pipe and casing protection. 300XT™ is known to consistently outlast the competition in lab and field tests. It produces minimum casing wear and maintains significantly more open-hole wear resistance versus competing casing-friendly products – qualities needed to protect the drill pipe tool joints from rapid wear found in highly abrasive drilling conditions.

For customers seeking the durability of the 300XT™ with improved ease of application and the ability to re-apply over competitive materials, the 300XT™ should be considered.

Benefits:-

Source :- https://www.arncotech.com/300-xt/

Arnco 100XT™ was created using an innovative metallurgical design that delivers both adequate tool joint protection and excellent casing wear protection. Arnco 100XT™ delivers a crack-free deposit and exhibits casing wear among the lowest ever measured.

The inherently low coefficient of friction that is a feature of Arnco 100XT™’s metallurgical characteristics significantly reduces wear caused by contact between the drill string, casing and marine risers and BOPs and can extend the economic life of all the equipment involved.

Arnco is proud of the 100XT™ with it’s proven track record since the late 1990’s as one of our legacy products. The key features of the 100XT™ wire is the non-cracking hardbanding and casing friendliness to maximize casing protection. For customers looking for a casing friendly only specification, the 100XT™ is easily the best choice.

Benefits:-

Source :- https://www.arncotech.com/100-xt/

Arnco’s BUXT™ is a high-quality, metal-cored wire for all build-up needs. Ideal for welding onto most steels comprising tubulars in the oilfield, BUXT™ is an easy-to-apply welding wire that produces a smooth weld bead free of cracks. Arnco’s BUXT™ is the ideal build-up wire to complement any of Arnco’s line of hardbanding products.

Benefits:-

Source :- https://www.arncotech.com/buxt/

Arnco’s 350XT® is a metal-cored wire that produces a highly wear-resistant, hard (greater than 60 HRC), tough, and casing-friendly, NON-CRACKING deposit. The ability to achieve such exceptional durability, while being casing-friendly and crack-free, is metallurgically based on carbides and borides that produce a grain structure forming tightly arranged hard phases interspersed in a strong, ductile matrix. The small nature of the carbides and borides puts less stress on the matrix allowing for a crack-free deposit and superior durability.

350XT® can easily be applied on new tooljoints or re-applied over itself without removal of the previous layer. The material can also be applied over Arnco’s 100XT™ and 150XT™, as well as most comparable products with proper procedures. When applied, 350XT® produces a smooth, crack-free deposit with very little spatter, requiring minimal post-weld cleanup. With 350XT®’s best-in-class wear resistance for non-cracking hardbanding solutions, you won’t need to reapply as often as competing products, improving your ROI. As the most durable, casing-friendly, and non-cracking hardbanding solution on the market you can’t go wrong with Arnco’s 350XT®.

Benefits :-

Source :- https://www.arncotech.com/350-xt/

Arnco’s 150XT™ is a durable, casing-friendly, and crack-free hardbanding wire and maintains the industry’s lowest casing wear rate for tool joint protection. The 150XT™ product was developed to be a crack-free, competitively priced hardbanding product with extremely low casing wear and high wear resistance for tool-joint protection. 150XT™ is a perfect solution to reduce the casing wear in areas of high side loading.

After years of continued success with Arnco’s legacy 100XT™, we set out to develop a hardbanding material with significantly improved durability while still maintaining the industry’s lowest casing wear rate. As a result, we developed 150XT™. With quadruple the wear resistance and double the durability as 100XT™, as well as being Arnco’s most casing-friendly product to date, we know we succeeded. For our customers seeking a balance between price, casing-friendliness and durability, 150XT™ offers the best hardbanding solution available.

The 150XT™ product is easy to apply and exhibits excellent weldability. It produces a smooth, crack-free deposit with very little spatter requiring minimal post-weld clean-up. 150XT™ is a similar compound to the 300XT™, except this wire is a non-cracking hardbanding solution. 150XT™ can be applied over itself an unlimited number of times without removal of the previous layer. It may also be applied over Arnco’s 100XT™ and 350XT®, as well as most comparable products using proper procedures.

Benefits :-

Source :- https://www.arncotech.com/150-xt/

300XT™ has long been considered the industry’s most wear-resistant hardbanding product and is a favored choice by many international operators and drilling contractors for drill pipe and casing protection. 300XT™ is known to consistently outlast the competition in lab and field tests. It produces minimum casing wear and maintains significantly more open-hole wear resistance versus competing casing-friendly products – qualities needed to protect the drill pipe tool joints from rapid wear found in highly abrasive drilling conditions.

For customers seeking the durability of the 300XT™ with improved ease of application and the ability to re-apply over competitive materials, the 300XT™ should be considered.

Benefits:-

Source :- https://www.arncotech.com/300-xt/

Arnco 100XT™ was created using an innovative metallurgical design that delivers both adequate tool joint protection and excellent casing wear protection. Arnco 100XT™ delivers a crack-free deposit and exhibits casing wear among the lowest ever measured.

The inherently low coefficient of friction that is a feature of Arnco 100XT™’s metallurgical characteristics significantly reduces wear caused by contact between the drill string, casing and marine risers and BOPs and can extend the economic life of all the equipment involved.

Arnco is proud of the 100XT™ with it’s proven track record since the late 1990’s as one of our legacy products. The key features of the 100XT™ wire is the non-cracking hardbanding and casing friendliness to maximize casing protection. For customers looking for a casing friendly only specification, the 100XT™ is easily the best choice.

Benefits:-

Source :- https://www.arncotech.com/100-xt/

Mr. Austin J. Wells, P.E.

Director of Quality & Technology

Mr. Paco McLaughlin

President

Mr Austin J. Wells, P.E.

Director of Quality & Technology

Mr Paco McLaughlin

President

Mr Austin J. Wells, P.E.

Director of Quality & Technology

Mr Paco McLaughlin

President

Mr Austin J. Wells, P.E.

Director of Quality & Technology

Mr Paco McLaughlin

President

Mr Austin J. Wells, P.E.

Director of Quality & Technology

Mr Paco McLaughlin

President

Mr Austin J. Wells, P.E.

Director of Quality & Technology

Mr Paco McLaughlin

President

*Energy Dais does not guarantee the correctness of the information provided.

Benchmark yourself against your main competitors

Peek into the hidden marketing strategies of your competitors, across industries and

Keyword research made easy and based on actual traffic statistics

Discover new opportunities while reducing risk by learning from your competitor's mistakess

Outbrain has been using SimilarWeb for over a year and it's been instrumental for our ability to analyze our competitive environment, benchmark our performance, keep track of industry trends, and generate new leads.