Site Supervision & Construction Support

J&P Engineering Ghana Ltd

Project Scope: Site Supervision & Construction Support for Boiler Canopy Steel...

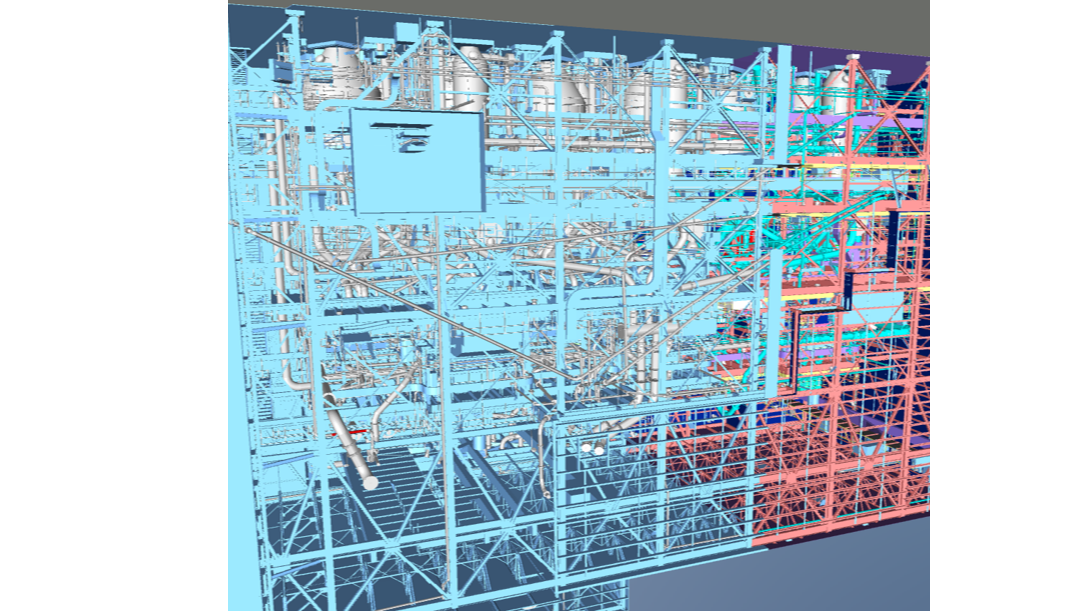

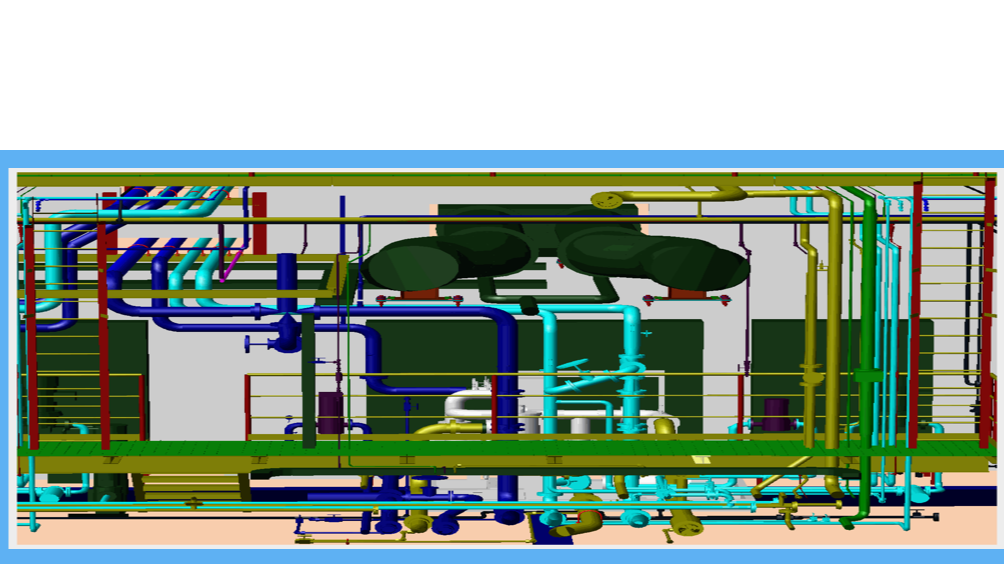

Project Scope: Site Supervision & Construction Support for Boiler Canopy Steel Structure, GHANA Client: J&P Engineering Ghana Ltd End client: Cargill Cocoa B.V. Project duration: 3 months Team Size: 15 Project Scope: Cargill Cocoa intended to build a new boiler room next to the existing boiler room, on their cocoa plant in Ghana, in the “free” zone of Tema. This boiler room consist of biomass boiler installation. The installation supported by a concrete footing, which is placed on a foundation soil. Over the installation a 14 metres high canopy, which is supported by a steel frame (columns and beams). An existing chimney, with a height of 30 metres and founded on a slab of 1.5×1.5 metres. Located in the southwest corner of the new boiler room and erection and commissioning amidst the new construction. Establishing proper communication with Client on the status of Steel Structure manufacturing. Managing all Construction and Installation.