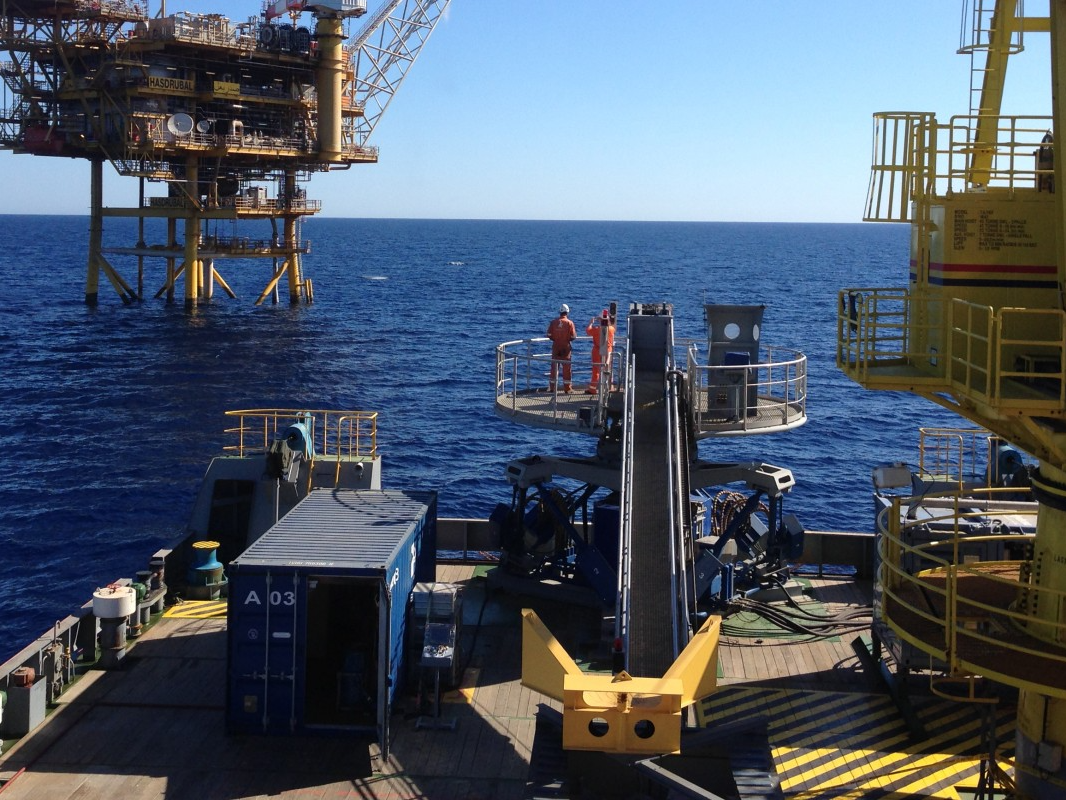

Re-installation of a lifeboat onto a platform

Talisman Sinopec Energy UK

In a refurbishment program to upgrade lifeboats on offshore platforms, Ampelman...

In a refurbishment program to upgrade lifeboats on offshore platforms, Ampelmann completed a second successful reinstallation using its full motion compensation technology. The eight-metric-ton lifeboat was kept completely stationary above the vessel deck, to allow lifting by the platform’s davit cranes. Traditionally, refurbished lifeboats are reinstalled on the offshore structure in the following manner: a platform supply vessel takes the lifeboat offshore, where it is lifted from the deck to the sea. Crew then enter the lifeboat, sail it under the offshore structure and attach the davit fall wires. The crew is removed from the lifeboat before lifting can commence. This operation is generally limited to calm weather and wave conditions, and requires challenging manhandling actions by the crew.